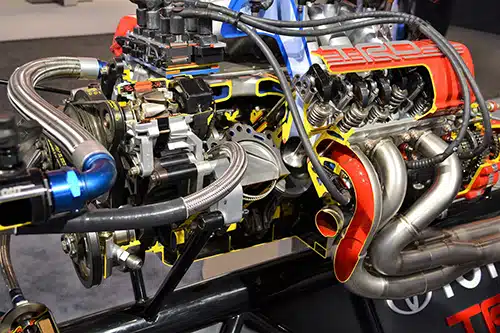

Tips Building A Racing Motor

How to rebuild a start to finish racing engine

Disassembling a complete engine involves a comprehensive process. Here are the general steps to disassemble the engine starting with the components you listed:

1. Disconnect the battery: Remove the negative battery cable to ensure safety and prevent electrical mishaps.

2. Drain fluids: Drain the engine oil, coolant, and any other fluids as necessary. Follow proper disposal procedures.

3. Remove the motor mounts: Loosen and remove the motor mounts to free the engine from the chassis. Use appropriate support equipment to safely lift and support the engine.

4. Disconnect electrical wires: Disconnect and label all electrical connections, including those to the alternator, starter, ignition system, and sensors. Remove any wire harnesses or brackets that may be obstructing access.

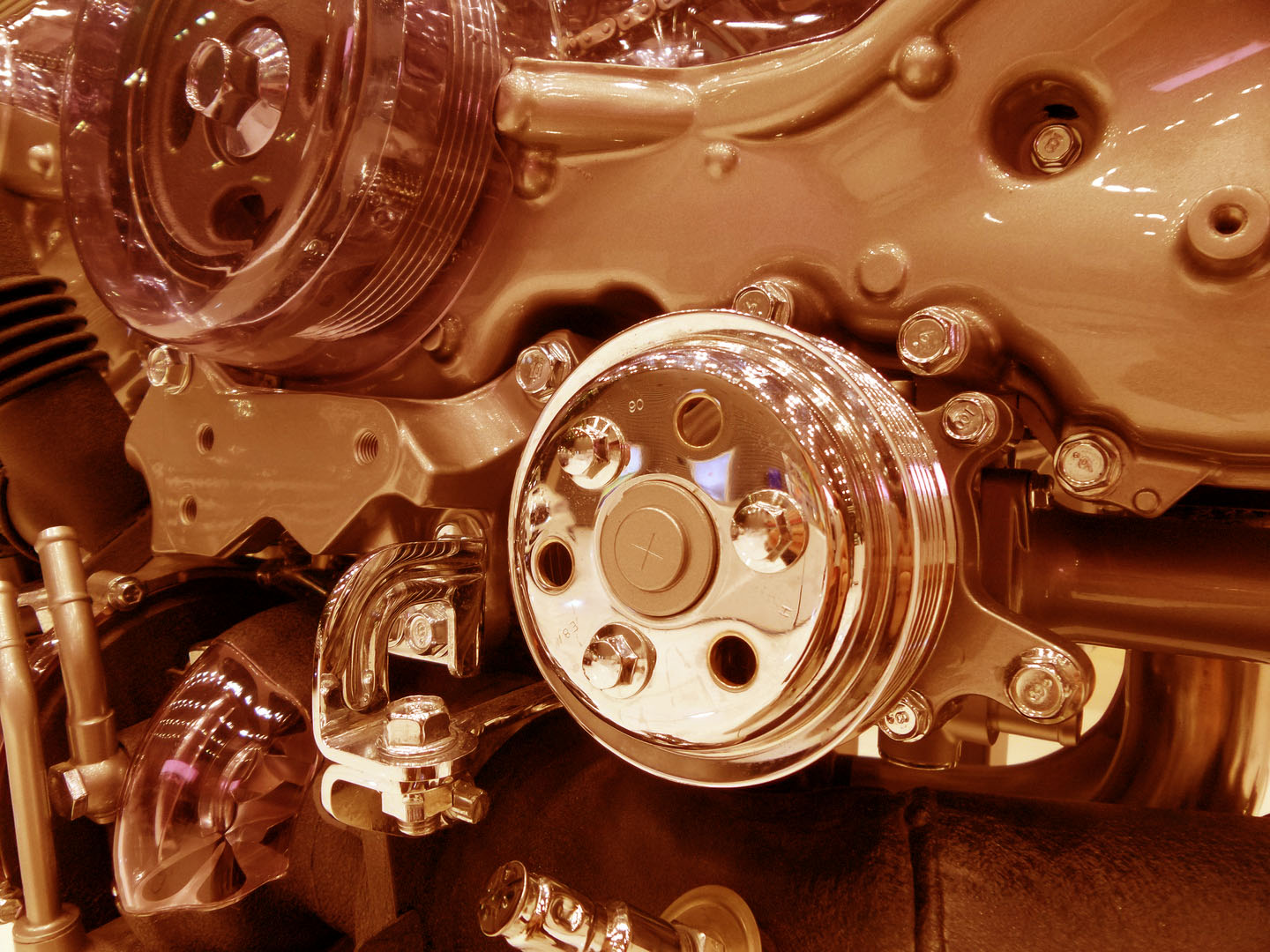

5. Remove belts: Loosen the tensioner and remove any belts, including the serpentine belt and timing belt/chain.

6. Remove the alternator, starter, and air conditioner: Detach the electrical connections and unbolt these components, removing them from the engine.

7. Disassemble the timing system: Remove the timing gear cover and related components. Depending on the engine, this may include the timing gears, chains, tensioners, and guides. Be cautious to follow the manufacturer’s instructions to avoid damaging the timing system.

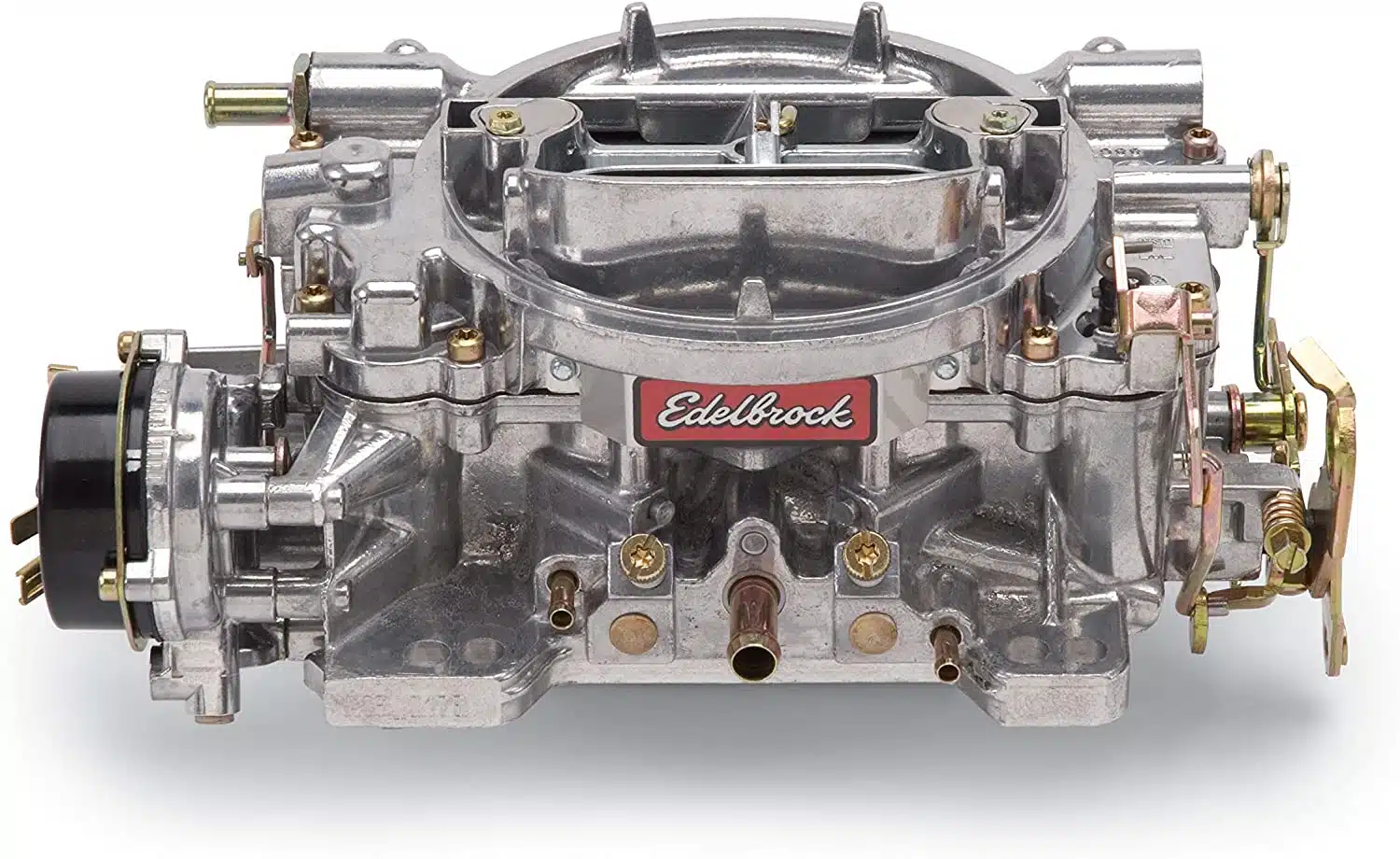

8. Remove the carburetor or fuel injection system: Disconnect the fuel lines and throttle linkage, and unbolt the carburetor or fuel injection system. Take note of any vacuum lines or sensors attached to these components.

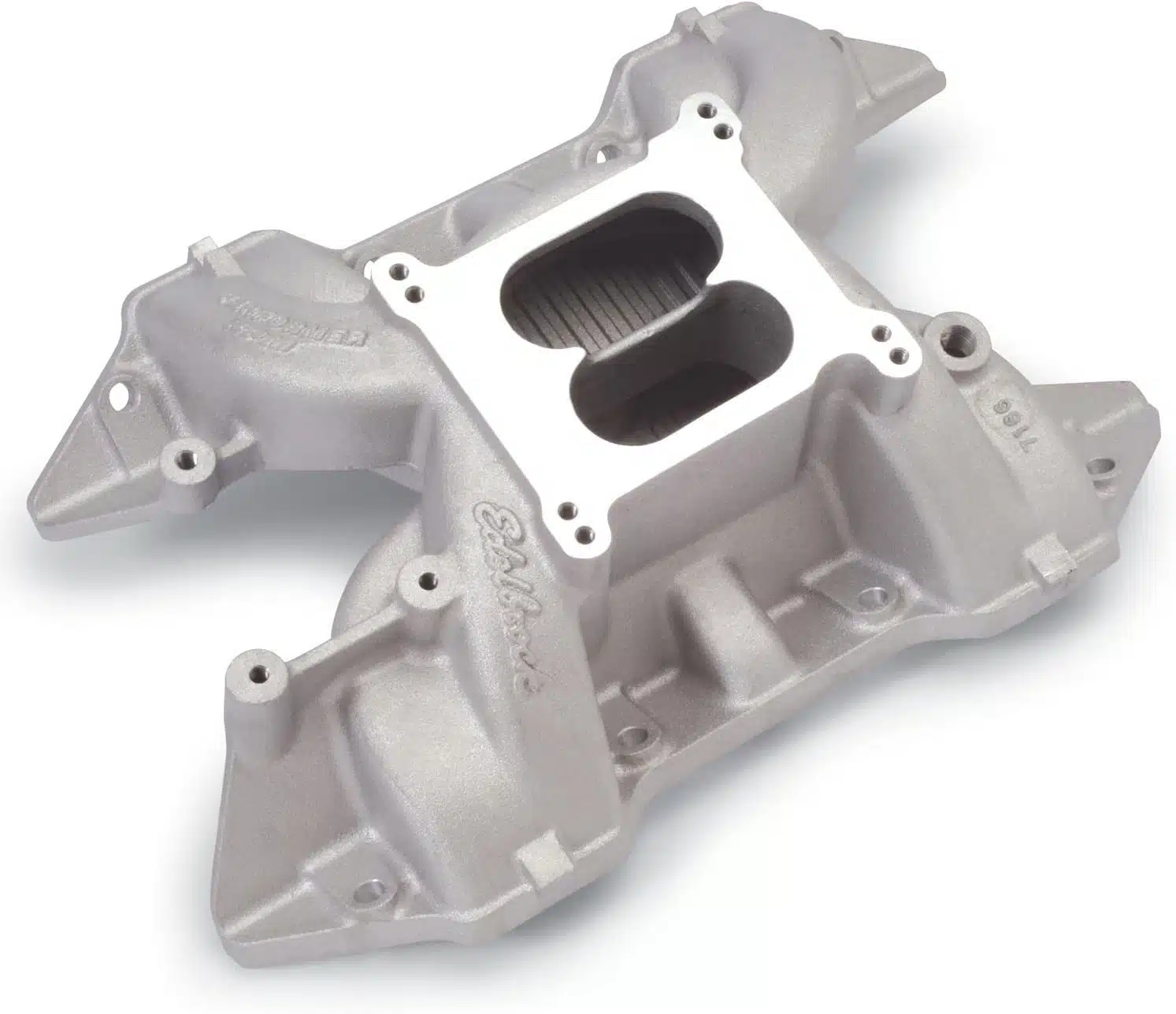

9. Remove intake manifolds and exhaust components: Disconnect the intake manifold, including any fuel injectors or carburetor mounting bolts. Remove the exhaust manifolds or headers, mufflers, and related components.

10. Remove gaskets and seals: Carefully scrape off any gaskets or seals between the engine components being disassembled. Take note of their locations for reassembly.

11. Disassemble the cylinder heads: Remove the valve covers, rocker arms, pushrods (if applicable), and then loosen and remove the cylinder head bolts. Lift off the cylinder heads, taking care not to damage the mating surfaces.

12. Remove valves, valve seats, and valve springs: Use a valve spring compressor tool to compress the valve springs and remove the retainers, allowing you to remove the valves. If necessary, remove and replace valve seats.

13. Remove the camshaft: Remove any camshaft retaining bolts or fasteners and gently slide out the camshaft.

14. Remove the pistons, rings, and bearings: Remove the oil pan and loosen and remove the connecting rod bolts. Push the pistons and connecting rods out of the cylinder bores. Remove the piston rings and main bearings.

15. Disassemble other components: Remove any remaining components such as the oil pump, engine block covers, freeze plugs, and other accessories.

Ensure you consult the specific repair manual or manufacturer’s guidelines for your engine model, as the disassembly process may vary. Take your time, stay organized, and exercise caution to prevent damage to the components.

To finish is a complex process that requires specialized knowledge and tools also. Here is a general overview of the steps involved:

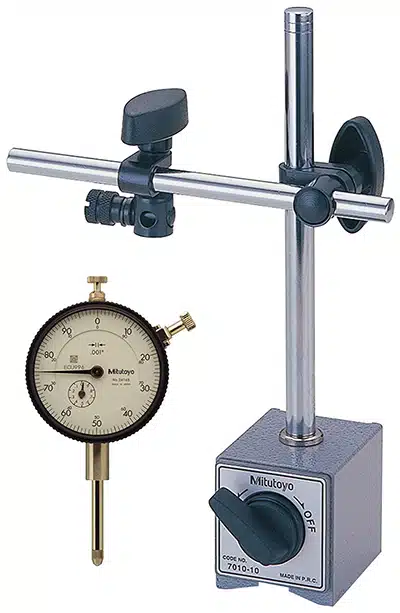

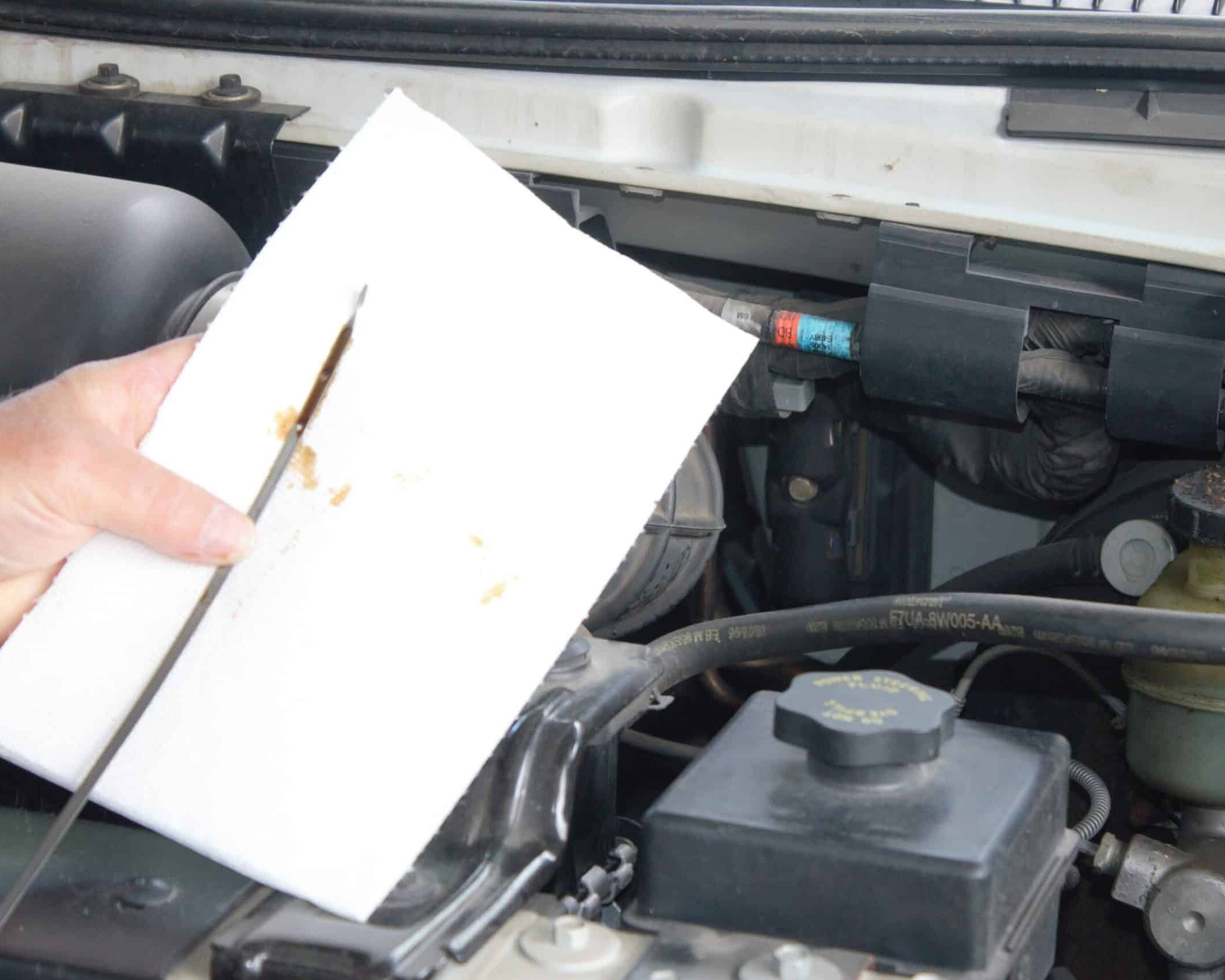

A. Inspection: Inspect all parts for wear and damage. Replace any parts that are damaged or worn beyond acceptable limits.

B. Machine work: Send the cylinder block, cylinder head, and other parts to a machine shop for boring, honing, and other necessary machining work.

C. Assembly: Assemble the engine using new or rebuilt parts, following the manufacturer’s specifications. Be sure to properly torque all fasteners and check clearances.

D. Break-in: Start the engine and run it through a proper break-in procedure, as specified by the manufacturer.

E. Tuning: Fine-tune the engine for optimal performance. This may include adjusting the ignition timing, carburetor settings, and other variables.

It is highly recommended to have the experience and a professionals help to complete this task as it is a very complex and technical process.

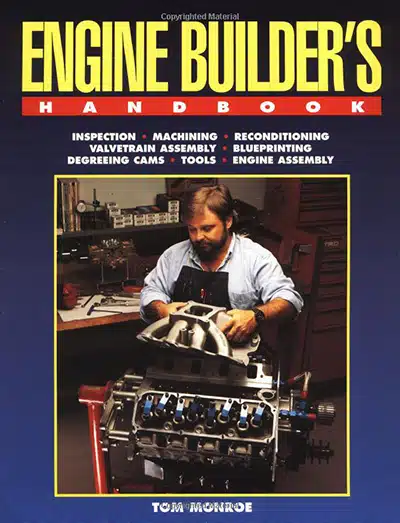

Pickup one our manuals, it’s a great source to refer to, Get It Here!

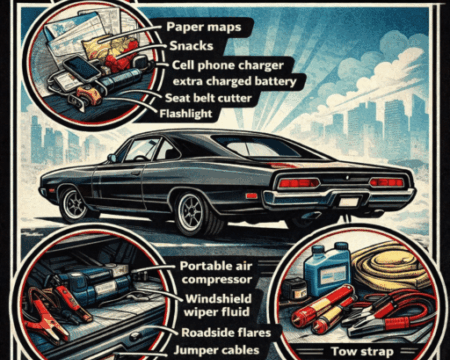

Visit Our Other Articles…