Camshaft Sensors: Their Important Function and Impact on Engine Performance

by CarDudes.net

Introduction: Modern vehicles rely on sophisticated engine management systems to optimize performance, fuel efficiency, and emissions. Among the various sensors and components in these systems, the camshaft sensor holds a crucial position. In this article, we will explore the function of camshaft sensors, their inner workings, and their significant impact on engine performance.

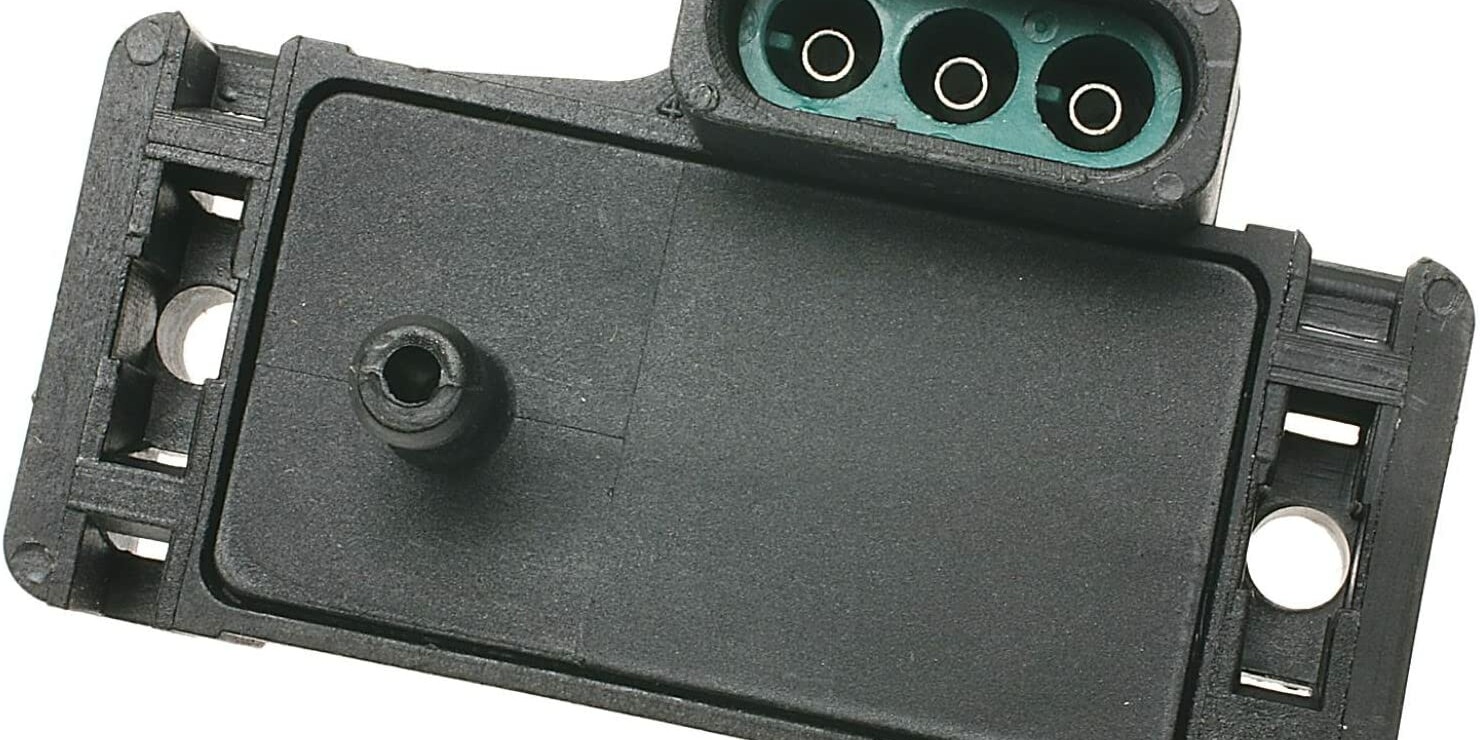

I. Understanding Camshaft Sensors: A. Definition and Purpose: Camshaft sensors, also known as cam position sensors or CMP sensors, are electronic devices designed to monitor the position and speed of the camshaft(s) in an internal combustion engine. They provide vital information to the engine control unit (ECU), enabling precise control of fuel injection, ignition timing, and other engine functions.

B. Types of Camshaft Sensors: There are primarily two types of camshaft sensors: Hall effect sensors and magnetic reluctance sensors. While they differ in construction and operating principles, both types serve the same purpose of monitoring camshaft position and speed.

II. How Camshaft Sensors Work:

A. Camshaft Position and Speed Detection:

-

Hall Effect Sensors: Hall effect sensors consist of a Hall effect element, a magnet, and supporting electronics. As the camshaft rotates, the magnet passes in close proximity to the Hall effect element, generating a voltage signal that varies with the position and speed of the camshaft.

-

Magnetic Reluctance Sensors: Magnetic reluctance sensors utilize a reluctor wheel, which is mounted on the camshaft, and a magnetic coil surrounding it. As the reluctor wheel’s teeth pass by the magnetic coil, changes in magnetic field strength are detected, generating an electrical signal that corresponds to camshaft position and speed.

B. Signal Generation and Transmission: Once the camshaft sensor detects the position and speed of the camshaft, it generates an electrical signal that is transmitted to the ECU. The ECU uses this information to make precise adjustments to various engine parameters, including fuel injection timing, ignition timing, and valve operation.

III. The Significance of Camshaft Sensors in Engine Performance: A. Fuel Injection Timing: Accurate fuel injection timing is crucial for efficient combustion and power delivery. Camshaft sensors provide real-time information about the position of the camshaft, allowing the ECU to determine the optimal timing for fuel injection. This ensures precise delivery of fuel to each cylinder at the right moment, maximizing power and fuel efficiency.

B. Ignition Timing: Proper ignition timing is essential for reliable engine performance. By monitoring the camshaft position, camshaft sensors help the ECU determine the precise timing for ignition spark generation. This ensures that the spark plug fires at the correct moment, promoting efficient combustion and preventing issues like misfires and engine knock.

C. Valve Operation: Camshaft sensors also play a crucial role in controlling valve operation within the engine. The ECU relies on the position information provided by the sensors to synchronize the opening and closing of the engine’s valves. This precise valve timing ensures optimal airflow, efficient combustion, and overall engine performance.

D. Variable Valve Timing (VVT) Systems: In vehicles equipped with variable valve timing systems, camshaft sensors are instrumental in regulating valve timing. These systems can adjust the camshaft position and duration of valve opening and closing events based on engine conditions. Camshaft sensors provide critical input to the VVT system, allowing the ECU to optimize valve timing for different driving conditions, enhancing performance and fuel efficiency.

IV. Common Issues and Maintenance Considerations: A. Sensor Malfunction: Camshaft sensors can malfunction due to various factors such as electrical issues, sensor damage, or contamination. A faulty sensor may provide inaccurate or no signal to the ECU, resulting in adverse effects on engine performance. Regular maintenance and inspection can help detect and address sensor-related problems in a timely manner.

B. Sensor Failure and Replacement: When a camshaft sensor fails, it is necessary to replace it with a new sensor that meets the specifications of the vehicle’s engine and electronic system. It is crucial to use a compatible and high-quality sensor to ensure accurate signal transmission and proper functioning.

C. Sensor Cleaning and Calibration: In some cases, sensor issues may be caused by sensor contamination or misalignment. Cleaning the sensor and ensuring proper alignment can sometimes resolve minor issues. However, calibration and adjustment procedures should only be performed by trained professionals to avoid further complications.

Conclusion: Camshaft sensors are vital components in modern engine management systems, providing crucial information about camshaft position and speed to the ECU. By enabling precise control of fuel injection timing, ignition timing, and valve operation, camshaft sensors play a pivotal role in optimizing engine performance, fuel efficiency, and emissions. Regular maintenance, timely replacement, and proper calibration of camshaft sensors are essential to ensure their accurate functioning and contribute to a well-performing engine.

Camshaft sensors are essential components in a vehicle’s engine management system. They monitor the position and speed of the camshaft and provide crucial information to the engine control unit (ECU). When a camshaft sensor starts to fail or malfunctions, it can lead to various symptoms and performance issues. Here are some signs that might indicate it’s time to replace a camshaft sensor:

-

Check Engine Light: A malfunctioning camshaft sensor can trigger the check engine light on the vehicle’s dashboard. The ECU detects irregularities in the sensor’s signal and generates a fault code related to the camshaft position sensor. A diagnostic scan can help identify the specific error code.

-

Engine Misfires: A faulty camshaft sensor can cause improper fuel injection timing or inaccurate ignition timing. This can result in engine misfires, where one or more cylinders fail to ignite the fuel-air mixture correctly. Misfires can lead to rough idling, reduced engine power, and potentially, an increase in exhaust emissions.

-

Difficulty Starting the Engine: The camshaft sensor provides crucial information to the ECU during the engine’s startup phase. If the sensor fails, it may not send accurate signals, causing difficulties in starting the engine. The engine may take longer to crank, or it may not start at all.

-

Stalling or Sudden Engine Shutdown: A malfunctioning camshaft sensor can cause intermittent loss of signal or incorrect readings. This can lead to stalling or sudden engine shutdown while driving, posing a safety risk. If the sensor is unable to provide accurate information about the camshaft’s position, the ECU may shut down the engine as a precautionary measure.

-

Reduced Fuel Efficiency: When the camshaft sensor is faulty, it can disrupt the engine’s timing and fuel injection processes. This can result in poor combustion efficiency, leading to decreased fuel economy. If you notice a significant drop in your vehicle’s fuel efficiency without any other apparent causes, a malfunctioning camshaft sensor could be a possible culprit.